Page 39 - 《精细化工》2020年第4期

P. 39

第 4 期 潘 一,等: 聚合物稳泡剂耐温性研究进展 ·673·

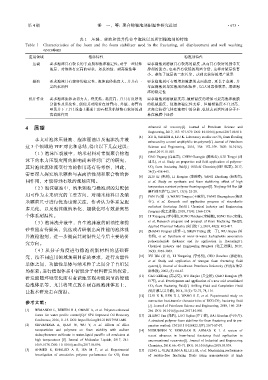

表 1 压裂、驱油和洗井作业中泡沫以及所用稳泡剂的特性

Table 1 Characteristics of the foam and the foam stabilizer used in the fracturing, oil displacement and well washing

operations

应用领域 泡沫特性 稳泡剂特性

压裂 要求泡沫具有较长的半衰期和泡沫稳定性,对于一些特殊 要求稳泡剂溶液具有较高的黏度,从而具有较好的携带支

地层,对泡沫有更高的要求,如抗油性、耐高温性等 撑剂的能力;也要具有较低的残渣含量,这样对储层伤害

小,避免了地层的二次污染,达到比较好的增产效果

驱油 要求泡沫具有较好的稳定性,泡沫流体黏度大,并具有一 要求稳泡剂可有效增加液膜的表面黏度,延长半衰期,并

定的抗油性 考虑稳泡剂与发泡剂的配伍性,以达到最佳效果,增强泡

沫的稳定性

洗井作业 要求泡沫流体动切力大,密度低,黏度高,并具有良好的 要求稳泡剂溶液黏度高,液相黏度的增加可提高泡沫液膜

分散性及乳化性,能使其对附着在油管内、外壁、套管内 的机械强度,使泡沫稳定性变好,但液相黏度不宜过高,

壁及井下工具(设备)通道上的石蜡及粘结物有较好的剥 过高会妨碍气体在液相中的分散,也使表面活性剂分子不

离清除作用 易在液膜中迁移

4 展望 enhanced oil recovery[J]. Journal of Petroleum Science and

Engineering, 2017, 157: 971-979. DOI: 10.1016/j.petrol.2017.08.018.

[4] XU X, SAEEDI A, LIU K. Laboratory studies on CO 2 foam flooding

本文对泡沫压裂液、泡沫驱油以及泡沫洗井液

enhanced by a novel amphiphilic ter-polymer[J]. Journal of Petroleum

这 3 个领域的 PEF 对比和总结,得出以下几点建议: Science and Engineering, 2016, 138: 153-159. DOI: 10.1016/j.

(1)泡沫压裂液中,纳米材料对常规聚合物泡 petrol.2015.10.025.

[5] GAO Yagang (高亚罡), CHEN Guangjie (陈光杰), LIU Tongyi (刘

沫下的水力压裂应用的影响尚未得到广泛的研究, 通义), et al. Study on properties and field application of polymer-

其对泡沫流体流变行为的作用还有待考察,因此, CO 2 foam fracturing fluid[J]. Oilfield Chemistry(油田化学), 2017,

34(3): 438-443.

需要深入探究纳米颗粒与表面活性剂和聚合物的协

[6] ZHU Li (朱利), LI Hongtao (李洪涛), YANG Zhaoliang (杨兆亮),

同作用,才能得到有效的现场应用。 et al. Study on synthesis and foam stabilizing effect of high

(2)泡沫驱油中,纳米颗粒与稳泡剂的复配使 temperature resistant polymer foaming agent[J]. Xinjiang Oil Gas (新

疆石油天然气), 2017, 13(3): 25-28.

用可作为未来研究的主要方向,对纳米材料以及纳 [7] PAN Yi (潘一), WANG Tongyu (王瞳煜), YANG Shuangchun (杨双

米颗粒尺寸进行优选也需关注,作者认为体系复配 春 ), et al. Research and application progress of viscoelastic

surfactant fracturing fluid[J]. Chemical Industry and Engineering

多元化,以及泡沫微纳米化、超微化可有效提高整

Progress (化工进展), 2018, 37(4): 1566-1574.

个体系耐温性。 [8] LI Xiaogang (李小刚), SONG Zhichao (宋峙潮), SONG Rui (宋瑞),

(3)泡沫洗井液中,自生泡沫液的耐油性和携 et al. Research progress and prospect of foam fracturing fluid[J].

Applied Chemical Industry (应用化工), 2019, 48(2): 412-417.

砂性能有待提高,优选或者研制出高性能的泡沫洗 [9] ZHANG Fengsan (张锋三), SHEN Yiding (沈一丁), WU Jinqiao (吴

井液稳泡剂,进一步提高其耐温性是今后主要的研 金桥), et al. Synthesis of water-in-water hydrophobic association

polyacrylamide thickener and its application in fracturing[J].

究方向。

Chemical Industry and Engineering Progress (化工进展), 2017,

(4)从分子角度进行稳泡剂新材料的基础研 36(8): 3058-3065.

究,按不同应用领域预期目标的要求,进行功能性 [10] XU Wei (许卫), LI Yongming (李勇明), GUO Jianchun (郭建春),

et al. Study and application of nitrogen foam fracturing fluid

单体之间、功能性单体与纳米粒子之间分子自组装 system[J]. Journal of Southwest Petroleum University (西南石油学

的探索;进行稳泡体系中智能分子材料研发的探索, 院学报), 2002, (3): 64-67.

[11] GAO Zhiliang (高志亮), WU Jinqiao (吴金桥), QIAO Hongjun (乔

研发能随环境变化而有意识地实现功能调节的智能

红军), et al. Development and application of a new acid crosslinked

稳泡体系等,尤其将重点放在耐高温泡沫体系上, CO 2 foam fracturing fluid[J]. Drilling Fluid and Completion Fluid

让技术研发走在前沿。 (钻井液与完井液), 2014, 31(2): 72-75, 78, 101.

[12] LUO X R, REN X J, WANG S Z, et al. Experimental study on

参考文献: convection heat-transfer characteristics of BCG-CO 2 fracturing fluid

[J]. Journal of Petroleum Science and Engineering, 2018, 160: 258-

[1] HEMANDO L, BERTIN H J, OMARI A, et al. Polymer-enhanced 266. DOI: 10.1016/j.petrol.2017.10.050.

foams for water profile control[C]// SPE Improved Oil Recovery [13] ZHENG Yan (郑焰), LUO Yujian (罗于建), BAI Xiaodan (白小丹).

Conference, 2016, 11-13. DOI: https://doi.org/10.2118/179581-MS. A structural polymer foam stabilizer for foam fracturing and its pre-

[2] SRIVASTAVA A, QIAO W, WU Y, et al. Effects of silica paration method: CN 201511028822.1[P]. 2017-07-07.

nanoparticles and polymers on foam stability with sodium [14] NURUDEEN Y, ESWARAN P, AHMAD K I. A review of

dodecylbenzene sulfonate in water-liquid paraffin oil emulsions at recent advances in foam-based fracturing fluid application in

high temperatures [J]. Journal of Molecular Liquids, 2017, 241: unconventional reservoirs[J]. Journal of Industrial and Engineering

1069-1078. DOI: 10. 1016/j.molliq.2017.06.096. Chemistry, 2018, 66: 45-71. DOI: 10.1016/j.jiec.2018.05.039.

[3] AHMED S, KHALED A E, ISA M T, et al. Experimental [15] FENG L, GHAITHAN A M, LI L M, et al. Maximizing performance

investigation of associative polymer performance for CO 2 foam of residue-free fracturing fluids using nanomaterials at high