Page 102 - 《精细化工》2022年第8期

P. 102

·1602· 精细化工 FINE CHEMICALS 第 39 卷

的弱黏附力 [16] ,裸银纳米线电极中的纳米线在机械

弯曲过程中发生滑移,导致线结处接触不良甚至断

开,使得电阻上升。而复合电极中的导电网络半嵌

入聚合物膜,增大了导电网络与基底之间的附着力,

减小了滑移程度,因此,电阻变化较小,复合电极

表现出更好的机械柔韧性。

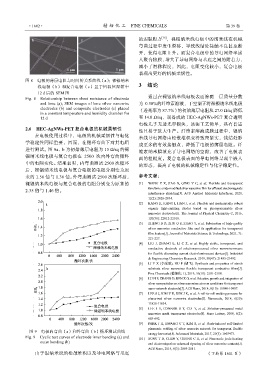

图 8 电极的薄层电阻与时间的关系曲线(a);裸银纳米

线电极(b)和复合电极(c)置于恒温恒湿箱中 3 结论

12 d 后的 SEM 图

Fig. 8 Relationship between sheet resistance of electrode 通过在裸银纳米线电极表面涂覆一层质量分数

and time (a); SEM images of bare silver nanowire 为 0.50%的纤维素溶液,于室温下将裸银纳米线电极

electrodes (b) and composite electrodes (c) placed (透光率为 87.7%)的初始薄层电阻从 27.0 Ω/sq 降低

in a constant temperature and humidity chamber for

12 d 至 14.0 Ω/sq,制备成的 HEC-AgNWs-PET 复合透明

电极几乎无透光率损失,该法工艺简单,具有普适

2.6 HEC-AgNWs-PET 复合电极的机械柔韧性

性且易于放大生产。纤维素溶液成膜过程中,银纳

在电极使用过程中,电极的机械柔韧性与电化

米线导电网络由松散堆积变得致密紧实,线结处形

学稳定性同样重要,因而,在循环弯曲下对其电阻

成更多的有效接触点,降低了电极的薄层电阻。纤

进行测试。图 9a、b 为初始薄层电阻为 15 Ω/sq 的裸

维素纳米膜填充了导电网络的空隙,改善了电极表

银纳米线电极与复合电极在 2500 次内外弯曲循环 面的粗糙度。复合电极表面的导电网络呈现半嵌入

中的电阻变化。结果表明,内弯曲测试 2500 次循环

的形态,提高了电极的机械稳定性与化学稳定性。

后,裸银纳米线电极与复合电极的电阻分别变为原

来的 1.56 倍与 1.36 倍。外弯曲测试 2500 次循环后, 参考文献:

裸银纳米线电极与复合电极的电阻分别变为原来的 [1] WANG Z X, JIAO B, QING Y C, et al. Flexible and transparent

ferroferric oxide-modified silver nanowire film for efficient electromagnetic

2.35 倍与 1.46 倍。

interference shielding[J]. ACS Applied Materials Interfaces, 2020,

12(2): 2826-2834.

[2] KANG H, KANG I, HAN J, et al. Flexible and mechanically robust

organic light-emitting diodes based on photopatternable silver

nanowire electrodes[J]. The Journal of Physical Chemistry C, 2016,

120(38): 22012-22018.

[3] ZHENG B D, ZHU Q S, ZHAO Y, et al. Fabrication of high-quality

silver nanowire conductive film and its application for transparent

film heaters[J]. Journal of Materials Science & Technology, 2021, 71:

221-227.

[4] LIU J, ZHANG L, LI C Z, et al. Highly stable, transparent, and

conductive electrode of solution-processed silver nanowire-mxene

for flexible alternating-current electroluminescent devices[J]. Industrial

& Engineering Chemistry Research, 2019, 58(47): 21485-21492.

[5] LI Y X (李禹欣), HU F (胡飞). Synthesis and properties of starch

substrate silver nanowires flexible transparent conductive films[J].

Fine Chemicals (精细化工), 2019, 36(10): 2101-2108.

[6] LU H F, ZHANG D, REN X G, et al. Selective growth and integration of

silver nanoparticles on silver nanowires at room conditions for transparent

nano-network electrode[J]. ACS Nano, 2014, 8(10): 10980-10987.

[7] LEE S J, KIM Y H, KIM J K, et al. A roll-to-roll welding process for

planarized silver nanowire electrodes[J]. Nanoscale, 2014, 6(20):

11828-11834.

[8] LEE J Y, CONNOR S T, CUI Y, et al. Solution-processed metal

nanowire mesh transparent electrodes[J]. Nano Letters, 2008, 8(2):

689-692.

[9] PARK J H, HWANG G T, KIM S, et al. Flash-induced self-limited

plasmonic welding of silver nanowire network for transparent flexible

图 9 电极内弯曲(a)和外弯曲(b)循环测试曲线

energy harvester[J]. Advanced Materials, 2017, 29(5): 1603473.

Fig. 9 Cyclic test curves of electrode inner bending (a) and [10] SONG T B, CHEN Y, CHUNG C H, et al. Nanoscale joule heating

outer bending (b) and electromigration enhanced ripening of silver nanowire contacts[J].

ACS Nano, 2014, 8(3): 2804-2811.

由于银纳米线的松散堆积以及导电网络与基底 (下转第 1611 页)