Page 69 - 201809

P. 69

第 9 期 张 通,等: 酶解玉米秸秆残渣制备聚氨酯硬质泡沫 ·1495·

–1

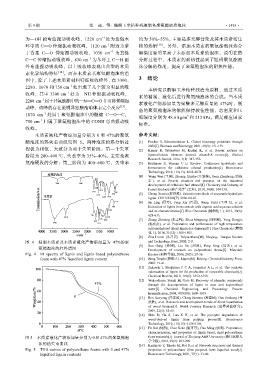

为—OH 的弯曲振动吸收峰,1220 cm 处为愈创木 约为 50%~55%,主要是多元醇骨架及其木质素衍生

–1

环中的 C==O 伸缩振动吸收峰,1120 cm 附近为紫 物的热解 [16] 。另外,添加木质素的聚氨酯泡沫热分

丁香基 C==O 伸缩振动吸收峰,1030 cm –1 为直链 解温度要明显高于未添加木质素的泡沫,说明在热

–1

C—C 伸缩振动吸收峰,830 cm 为苯环上 C—H 面 分解过程中,木质素的耐热性起到了阻碍聚氨酯泡

外弯曲振动吸收峰,以上吸收峰表现出典型的木质 沫分解的作用,提高了聚氨酯泡沫的耐热性能。

素化学结构特征 [14] 。而在木质素基聚氨酯泡沫的谱

图中,除了上述木质素材料特征吸收峰外,在 3300、 3 结论

–1

2280、1070 和 750 cm 处出现了几个较为明显的吸 本研究以酶解玉米秸秆残渣为原料,通过木质

–1

收峰,其中 3300 cm 处为—NH 伸缩振动吸收峰, 素的精制、液化后进行聚氨酯泡沫的合成。当木质

–1

2280 cm 属于异氰酸酯中的—N==C==O 非对称伸缩振 素液化产物添加量为聚醚多元醇质量的 47%时,制

动峰,该峰的存在说明异氰酸酯单体未完全反应 [15] , 备的聚氨酯泡沫的依然保持较佳性能,芯密度和压

–1

1070 cm 处属于聚氨酯泡沫中的醚键 C—O—C, 缩强度分别为 48.6 kg/m 和 212 kPa,满足相应国家

3

–1

750 cm 归属于聚氨酯泡沫中的 CONH 弯曲振动吸

标准。

收峰。

木质素液化产物添加量分别为 0 和 47%的聚氨 参考文献:

酯泡沫的热失重曲线见图 5。两种泡沫的热分解过 [1] Fischer G, Schrattenholzer L. Global bioenergy potentials through

2050[J]. Biomass and Bioenergy, 2001, 20(3): 151-159.

程极为相似,大致分为两个失重阶段:第一个失重 [2] Kumar R, Tabatabaei M, Karimi K, et al. Recent updates on

阶段为 200~400 ℃,失重率为 35%~40%,主要是聚 lignocellulosic biomass derived ethanol-A review[J]. Biofuel

Research Journal, 2016, 3(1): 347-356.

氨酯硬段的分解;第二阶段为 400~600 ℃,失重率 [3] Brethauer S, Wyman C E. Review: Continuous hydrolysis and

fermentation for cellulosic ethanol production[J]. Bioresource

Technology, 2010, 101(13): 4862-4874.

[4] Wang Wen (王闻), Zhuang Xinshu (庄新姝), Yuan Zhenhong (袁振

宏 ), et al. Present situation and prospect on the industrial

development of cellulosic fuel ethanol[J]. Chemistry and Industry of

Forest Products (林产化学与工业), 2014, 34(4): 144-150.

[5] Cheng Xiansu (程贤甦). Extraction methods of enzymatic hydrolysis

lignin: CN1763208[P]. 2006-04-26.

[6] Jia Ling (贾玲), Feng Xia (冯霞), Wang Yafei (王亚飞), et al.

Extraction of lignin from corncob with organic acid aqueous solution

and its characterization[J]. Fine Chemicals (精细化工), 2013, 30(6):

628-633.

[7] Zhang Zhiming (张志鸣), Zhou Mingsong (周明松), Yang Dongjie

(杨东杰), et al. Preparation and performance of high temperature

sulfomethylated alkali lignin dye disperant[J]. Fine Chemicals (精细

化工), 2014, 31(12): 1500-1505.

[8] Zhu Lvmin (朱吕民). Polyurethane[M]. Nanjing:Jiangsu Science

图 4 精制木质素及木质素液化产物添加量为 47%的聚 and Technology Press, 2002: 2-9.

[9] Sun Gang (孙刚), Liu Yu (刘预), Feng Fang (冯芳), et al.

氨酯泡沫的红外谱图 Development of research on polyurethane foams[J]. Materials

Fig. 4 IR spectra of lignin and lignin-based polyurethane Review (材料导报), 2006, 20(3): 29-36.

foam with 47% liquefied lignin content [10] Jiang Tingda (蒋挺大). Lignin[M]. Beijing: Chemical Industry Press,

2008: 19-41.

[11] Zakzeski J, Bruijnincx P C A, Jongerius A L, et al. The catalytic

valorization of lignin for the production of renewable chemicals[J].

Chemical Review, 2010, 110(6): 3552-3599.

[12] Wahyudiono, Sasaki M, Goto M. Recovery of phenolic compounds

through the decomposition of lignin in near and supercritical

water[J]. Chemical Engineering and Processing: Process

Intensification, 2008, 47(9/10): 1609-1619.

[13] Ren Xueyong (任学勇), Chang Jianmin (常建民), Gou Jinsheng (苟

进胜), et al. Research and development trends of direct liquefaction

of wood biomass[J]. World Forestry Research (世界林业研究),

2009, 22(5): 62-65.

[14] Shen D, Gu S, Luo K H, et al. The pyrolytic degradation of

wood-derived lignin from pulping process[J]. Bioresource

Technology, 2010, 101(15): 6136-6146.

[15] He Kai (何凯), Chen Keke (陈可可), Guo Ming (郭明). Preparation,

characterization, and properties of lignin based, rigid polyurethane

图 5 木质素液化产物添加量分别为 0 和 47%的聚氨酯泡 foam materials[J]. Journal of Zhejiang A&F University (浙江农林大

学学报), 2012, 29(2): 203-209.

沫的热失重曲线 [16] Kurimoto Y, Takeda M, Doi S, et al. Network structures and thermal

Fig. 5 TGA curves of polyurethane foams with 0 and 47% properties of polyurethane films prepared from liquefied wood[J].

liquified lignin contents Bioresource Technology, 2001, 77(1): 33-40.