Page 75 - 《精细化工》2022年第9期

P. 75

第 9 期 吴 婷,等: PET/CA 根须状蓬松纳米纤维复合膜的制备及其烹饪油烟过滤性能 ·1793·

构提高了气体通量,降低过滤时的压阻;另一方 米纤维复合膜的孔径,导致过滤阻力略有上升。对

面,特殊表面润湿性(超疏水超亲油)加速油滴的 8∶2 PET/CA 纳米纤维复合膜进行 100 min 连续过

吸附和渗透,提升其油烟过滤效率。8∶2 PET/CA 纳 滤测试,结果如图 6c 所示。经 100 min 的连续测试

米纤维复合膜的油烟过滤循环性能测试如图 6b 所 后,其油烟过滤效率仍高于 90%;且随着过滤时间

示。经 20 次循环测试后,仍保持较高的过滤效率 的延长,过滤效率变化不大,其过滤阻力大致以

(≥91%)和较小的过滤阻力(≤43 Pa);其过滤阻 3 min/Pa 的速度上升,与图 6b 的测试结果一致。

力则呈阶梯形上升规律,每经 3~4 次循环,过滤阻 本文制备材料与文献已报道的油烟过滤材料的

力上升 1 Pa,这可能是由于所过滤的油性颗粒在根 过滤性能对比如表 2 所示。可以看出,本文所制备

须状蓬松纳米纤维复合膜中的聚结所致,被蓬松纤 的 PET/CA 根须状蓬松纳米纤维复合膜的过滤效率

维捕获的油性颗粒,从根须末端向根部汇集,在其 与过滤阻力均优于其他过滤材料。其初始过滤效率

根须端聚集成小液滴,经过多次循环过滤,小液滴 为 92%,初始过滤阻力仅为 36 Pa,在烹饪油烟过滤

在纤维根部交叉处逐渐聚结成大液滴,从而堵塞纳 领域处于领先地位。

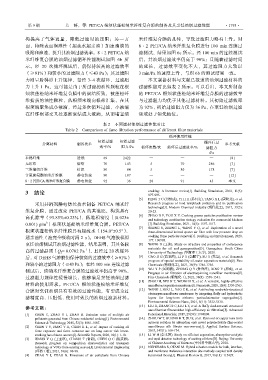

表 2 不同滤材油烟过滤性能对比

Table 2 Comparison of fume filtration performance of different filter materials

循环使用性能

初始过滤 初始过滤 循环后过

分离材料 制备技术 参考文献

效率/% 阻力/Pa 循环次数/次 循环后过滤效率/% 滤阻力

/Pa

木棉纤维 造纸 69 2422 — — — [8]

无纺布 熔喷 70 143 5 70 286 [7]

三维编织纤维 针织 80 84 5 80 178 [7]

含氟聚氨酯纳米纤维膜 静电纺丝 90 107 — — — [12]

8∶2 PET/CA 纳米纤维复合膜 静电纺丝 92 36 20 91 43 本文

3 结论 cooking: A literature review[J]. Building Simulation, 2018, 11(5):

977-995.

[5] FENG T C (冯铁成), YI H H (易红宏), TANG X L (唐晓龙), et al.

采用共溶剂静电纺丝技术制备 PET/CA 纳米纤 Research progress of food lampblack pollution and its purification

technology[J]. Modern Chemical Industry (现代化工), 2017, 37(3):

维复合膜,通过改变 PET/CA 的共混比,构筑具有 20-23.

高孔隙率(93.85%±0.23%)、低堆积密度〔(0.023± [6] ZHAO D F, YOU X Y. Cooking grease particles purification review

and technology combination strategy evaluation for commercial kitchens

3

0.001) g/m 〕根须状蓬松纳米纤维复合膜。PET/CA [J]. Building Simulation, 2021, 14(6): 1597-1617.

[7] SHENG Y, ZHENG L, WANG Y Q, et al. Exploration of a novel

根须状蓬松纳米纤维膜具有超疏水(154.0°±0.5°)、 three-dimensional knitted spacer air filter with low pressure drop on

超亲油性(油完全吸收时间 2 s)。DEHS 气溶胶模拟 cooking fume particles removal[J]. Building and Environment, 2020,

177: 106903.

烹饪油烟测试其油烟过滤性能,结果表明,其具备较 [8] WANG D (王迪). Study on structure and properties of coalescence

–1

高的过滤品质(Q f = 0.0702 Pa ),且经过 20 次循环 materials for oil and gasseparation[D]. Guangzhou: South China

University of Technology (华南理工大学), 2020.

后,对 DEHS 气溶胶仍保持较高的过滤效率(≥91%) [9] GAO D G (高党鸽), LI P Y (李鹏宇), SU Y (苏莹), et al. Research

progress of special wettability oil-water separation materials[J]. Fine

和较小的过滤阻力(≤43 Pa);在经 100 min 连续过滤 Chemicals (精细化工), 2021, 38(9): 1746-1756.

[10] WU Y P (吴延鹏), ZHONG Q Y (钟乔洋), XING Y (邢奕), et al.

测试后,该纳米纤维复合膜的过滤效率仍高于 90%, Progress in air filtration of electrospinning nanofiber membrane[J].

过滤阻力规律性缓慢增长,能够满足烹饪油烟过滤 Fine Chemicals (精细化工), 2021, 38(8): 1530-1541.

[11] ZHOU H, NIU H T, WANG H X, et al. A versatile, highly-effective

材料的使用需求。PET/CA 根须状蓬松纳米纤维复 nanofibrous separation membrane[J]. Nanoscale, 2020, 12(4): 2359-2365.

合膜对烹饪油烟具有有效的过滤性能,有望成为过 [12] WANG J, HOU L, YAO Z K, et al. Antifouling sandwich-structured

electrospun nanofibrous membranes by integrating fluffy and hydrophobic

滤精度高、压阻低、使用时效长的油烟过滤新材料。 layers for long-term airborne particulatematter segregation[J].

Environmental Science: Nano, 2021, 8(11): 3322-3330.

[13] LIU H, ZHANG S C, LIU L F, et al. A fluffy dual-network structured

参考文献: nanofiber/net filterenables high-efficiency air filtration[J]. Advanced

[1] CHEN C, ZHAO Y J, ZHAO B. Emission rates of multiple air Functional Materials, 2019, 29(39): 1904108.

pollutants generated from Chinese residential cooking[J]. Environmental [14] ZHOU W T, HUANG H T, DU S, et al. Removal of copper ions from

Science & Technology, 2018, 52(3): 1081-1087. aqueous solution by adsorption onto novel polyelectrolyte film-coated

[2] CHEN T Y, FANG Y H, CHEN H L, et al. Impact of cooking oil nanofibrous silk fibroin non-wovens[J]. Applied Surface Science,

fume exposure and fume extractor use on lung cancer risk innon- 2015, 345(1): 169-174.

smoking han chinese women[J]. Scientific Reports, 2020, 10(1): 1-10. [15] LI W H (李文辉). Study on efficient separation, absorption-catalytic

[3] WANG Y Q (王亚琪), CHANG T (常甜), CHEN Q C (陈庆彩). and rapid detection technology of cooking oil fume[D]. Beijing: University

Research progress on composition characteristics and treatment of Chinese Academy of Sciences (中国科学院大学), 2018.

technology of VOCs from catering sources[J]. Environmental Engineering [16] NISHIHARA S, OTANI M. Hybrid solvation models for bulk, interface,

(环境工程), 2021, 39(6): 90-98. and membrane: Reference interaction site methods coupled with density

[4] ZHAO Y J, ZHAO B. Emissions of air pollutants from Chinese functional theory[J]. Physical Review B, 2017, 96(11): 115429.