Page 218 - 《精细化工》2021年第4期

P. 218

·852· 精细化工 FINE CHEMICALS 第 38 卷

强,而影响抗张强度和耐破指数最大的因素正是纤维 良好的聚酯短纤维,且不影响纤维本身的热稳定性

间的结合力。改性后纤维有利于纸页强度性能的提升。 能。此法可用来替代对纤维有损伤或亲水性不足的改

性方法,拓展其在特种纸等高性能纸张方面的用途。

参考文献:

[1] LI P H (李鹏辉). Study on the performance of various chemical

fiber/pulp mixed paper[D]. Xi'an: Shaanxi University of Science and

Technology (陕西科技大学), 2017.

[2] GE Z, YUE H Y, SUN R J, et al. Properties of mortar produced with

recycled clay brick aggregate and PET[J]. Construction and Building

Materials, 2015, 93(9): 851-856.

[3] WAN J (万婧). Preparation of PET fibrid by precipitation method

and its papermaking property[D]. Xi'an: Shaanxi University of

Science and Technology (陕西科技大学), 2016.

[4] SUN Z X (孙召霞). Improvement mechanical properties for paper

made of PET fiber[D]. Xi'an: Shaanxi University of Science and

Technology (陕西科技大学), 2014.

[5] WU J D, CAI G Q, LIU J Q, et al. Eco-friendly surface modification

on polyester fabrics by esterase treatment[J]. Applied Surface

Science, 2014, 295(3): 150-157.

[6] PROROKOVA N P, KUMEEVAT Y, KUZ'MIN S M, et al.

Modification of polyester fibrous materials with surface barrier

discharge for making them more hydrophilic[J]. Russian Journal of

Applied Chemistry, 2016, 89(1): 147-154.

[7] MONTOYA-VILLEGAS K A, RAMIREZ-JIMENEZ A,

LICEA-CLAVERIE A, et al. Surface modification of polyester-fabric

with hydrogels and silver nanoparticles: Photochemical versus

gamma irradiation methods[J]. Materials, 2019, 12(20): 1-18.

[8] ABDELGHAFFAR F, ABDELGHAFFAR R A, RASHED U M, et

al. Highly effective surface modification using plasma technologies

toward green coloration of polyester fabrics[J]. Environmental

Science and Pollution Research, 2020, 27(23): 1-13.

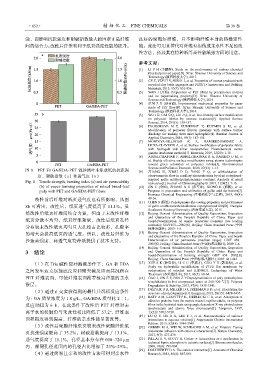

图 8 PET 和 GA/EDA-PET 混抄阔叶木浆成纸的抗张强 [9] ZHANG H, ZHOU D D, YANG F Q, et al.Modulation of

度、耐破指数(a)和透气度(b) electroosmotic flow in capillary electrophoresis by plant polyphenol-

Fig. 8 Tensile strength, bursting index (a) and air permeability inspired gallic acid/polyethyleneimine coatings: Analysis of small

molecules[J]. Journal of Chromatography B: 2019, 1124(5): 7-16.

(b) of paper-forming properties of mixed broad-leaf [10] JIN C (金灿), ZHANG X Y (张雪彦), XIONG K (熊凯), et al.

pulp with PET and GA/EDA-PET fibers Progress in preparation and utilization of gallic acid derivatives[J].

Biomass Chemical Engineering (生物质化学与工程), 2015, 49(4):

改性前后纤维对纸页透气度也有所影响,从图 49-56.

[11] CHEN S (陈思). Polydopamine-like coating-prepartion and performance

8b 可看出,改性后,纸页透气度提高了 11.1%。虽 of gallic acid/hexamethelinediamine copolymerized film[D]. Chengdu:

Southwest Jiaotong University (西南交通大学), 2015.

然改性后纸页纤维间结合力强,但由于未改性纤维 [12] Beijing General Administration of Quality Supervision, Inspection

and Quarantine of the People's Republic of China. Paper and

纸页分散不均匀,纸页纤维絮聚,改性后纸页孔径 board-Determination of tensile properties (constant rate loading

分布较未改性纸页均匀且大孔径占比较多,孔隙率 methods): GB/T453—2002[S]. Beijing: China Standard Press (中国

标准出版社), 2003: 1-5.

的增大会提高纸页的透气度。所以,改性后纤维为 [13] Beijing General Administration of Quality Supervision, Inspection

and Quarantine of the People's Republic of China. Paper and board-

抄造高强度、高透气度特种纸提供了技术支持。 Determination of air permeance (medium range): GB/T 458—

2008[S]. Beijing: China Standard Press (中国标准出版社), 2009: 1-4.

[14] Beijing General Administration of Quality Supervision, Inspection

3 结论 and Quarantine of the People's Republic of China. Paper and

board-Determination of bursting strength: GB/T 454—2002[S].

Beijing: China Standard Press (中国标准出版社), 2003: 441-443.

(1)在 Tris 碱性缓冲溶液条件下,GA 和 EDA [15] XUE S K (薛思快), LI C C (李成才), GUO Y H (郭玉海), et al.

Study on hydrophilic modification of PTFE flat membrane by

之间发生迈克尔加成反应和席夫碱反应而共沉积在 codeposition of catechol and KH560[J]. Technology of Water

Treatment (水处理技术), 2017, 43(7): 60-64.

PET 纤维表面,可使纤维表面附着极富羟基的亲水 [16] GAO J, JIN Z F, PAN Z Y.Depolymerization of poly (trimethylene

terephthalate) in hot compressed water at 240~320 ℃ [J]. Polymer

涂层。 Degradation & Stability, 2012, 97(9): 1838-1843.

(2)通过正交实验得到的最佳共沉积反应条件 [17] DREYER D R, MILLER D J, FREEMAN B D, et al. Elucidating the

structure of poly(dopamine)[J]. Langmuir, 2012, 28(15): 6428-6435.

为:GA 质量浓度为 1.0 g/L,GA/EDA 质量比 2∶1, [18] BATY A M, LEAVITT P K, SIEDLECKI C A, et al. Adsorption of

adhesive proteins from the marine mussel, mytilus edulis, on polymer

反应时间为 6 h,在此条件下改性后 PET 纤维对去 films in the hydrated state using angle dependent X-ray photoelectron

spectroscopy and atomic force microscopy[J]. Langmuir, 1997,

离子水的接触角与未改性相比降低了 57.2°,纤维表 13(21): 5702-5710.

[19] LU Q Y, OH D X, LEE Y J, et al. Nanomechanics of cation-π

面粗糙度得到提高,纤维的亲水性能显著改善。 interactions in aqueous solution[J]. Angewandte Chemie International

Edition, 2013, 52(14): 3944-3948.

(3)改性后聚酯纤维纸页较未改性聚酯纤维纸 [20] GEBBIE M A, WEI W, SCHRADER A M, et al. Erratum: Tuning

页抗张强度提高了 35.2%,耐破指数提高了 13.1%, underwater adhesion with cation-π interactions[J]. Nature Chemistry,

2017, 9(7): 473-479.

透气度提高了 11.1%,孔径基本分布在 600~720 μm [21] PILLAI K V, SCOTT R. Cation-π interactions as a mechanism in

technical lignin adsorption to cationic surfaces[J]. Biomacromolecules,

内,相同孔径范围内的孔径占比增加了 23%~29%。 2009, 10(4): 798-804.

[22] DOUGHERTY D A. The cation-π interaction[J]. Accounts of Chemical

(4)通过简易且亲和的改性方法可得到亲水性 Research, 2013, 46(4): 885-893.