Page 186 - 《精细化工》2020年第4期

P. 186

·820· 精细化工 FINE CHEMICALS 第 37 卷

明整理棉织物燃烧增长速率变慢,火灾危险性也就 3 结论

越低 [24] 。整理棉织物的最大热释放速率(PHRR)

2

2

及 THR 分别为 57.9 kW/m 、2.9 MJ/m ,明显低于 (1)以亚磷酸二甲酯、丙烯酰胺、三聚氯氰为

2

2

纯棉织物的 203.5 kW/m 、6.0 MJ/m ,说明整理棉 原料分两步成功制备了无甲醛棉用磷-氮型阻燃剂,

1

织物在燃烧过程中释放的热量更少,阻燃剂通过促 通过 FTIR、 HNMR 和 31 PNMR 对阻燃剂结构进行

进纤维素形成炭层,隔绝了热量,使燃烧不易扩散。 了表征,并对棉织物进行了阻燃整理。

最后的残炭率也证明了这点,整理棉织物的残炭率为 (2)整理棉织物的纤维表面粗糙,出现了大量

23.1%,纯棉织物的残炭率为 1.0%,这也说明阻燃剂 颗粒,整理棉织物的 FTIR 谱图中存在阻燃剂的特

促进了纤维素脱水成炭,提高了棉织物的燃烧性能。 征吸收峰,证明阻燃剂成功整理到棉织物上。整理

棉织物的热稳定性得到了提高,在氮气和空气气氛

中最大热分解速率分别降低了 66.7%及 68.0%。整

理棉织物 LOI 提高到 31.0%,具有良好的离火自熄

性。CCT 表明整理棉织物的 HRR、THR 均有明显

降低。

本文合成的阻燃剂是一种水溶性好、效率高、

不含甲醛的棉用磷-氮型阻燃剂,未来在家装等方面

具备广阔的应用前景。

参考文献:

[1] XIE L, GAO A Q, ZHANG Y S, et al. Flame retardant finishing of

cotton fabric based on synergistic compounds containing boron and

nitrogen[J]. Carbohydrate Polymers, 2013, 98(1): 706-710.

[2] CHEN B (陈兵), DONG C H (董朝红), ZHU P (朱平), et al. Study

on flame retardant and antibacterial properties of cotton fabric with

N,N-di (ethyl phosphate) biguanide[J]. Journal of Cellulose Science

and Technology (纤维素科学与技术), 2019, 27(1): 28-35.

[3] JIANG Z M, LI H, HE Y W, et al. Flame retardancy and thermal

behavior of cotton fabrics based on a novel phosphorus-containing

siloxane[J]. Applied Surface Science, 2019, 479: 765-775.

[4] MUHAMMED K, EREN T. Synthesis of phosphorus-containing

flame retardants and investigation of their flame retardant behavior in

textile applications[J]. Journal of Applied Polymer Science, 2019,

36(136): 47935.

[5] ZHANG M J (张美静), LI W X (李文霞), ZHAO F X (赵非祥).

Preparation and application of durable non-formaldehyde flame

retardants for cotton fabric[J]. Textile Auxiliaries (印染助剂), 2016,

33(1): 7-12.

[6] MA D, LI J. Synthesis of a bio-based triazine derivative and its

effects on flame retardancy of polypropylene composites[J]. Journal

of Applied Polymer Science, 2019, 137(1): 245-253.

[7] WAN C Y, TIAN P Y, LIU M S, et al. Synthesis of a phosphorus-

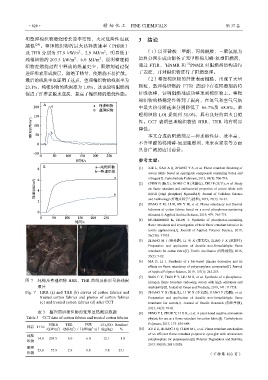

图 7 纯棉及整理织物 HRR、THR 曲线及锥形量热残炭 nitrogen flame retardant endowing cotton with high whiteness and

照片 washability[J]. Industrial Crops and Products, 2019, 141: 111738.

Fig. 7 HRR (a) and THR (b) curves of cotton fabrics and [8] ZHANG Y G (张亚光), LI W X (李文霞), JIANG P (姜鹏), et al.

treated cotton fabrics and photos of cotton fabrics Preparation and application of durable non-formaldehyde flame

(c) and treated cotton fabrics (d) after CCT retardants for cotton[J]. Journal of Textile Research (纺织学报),

2013, 34(3): 76-81

表 3 整理前后棉织物的锥形量热测试数据 [9] FENG Y J, ZHOU Y, LI D K, et al. A plant-based reactive ammonium

Table 3 CCT data of cotton fabrics and treated cotton fabrics phytate for use as a flame-retardant for cotton fabric[J]. Carbohydrate

PHRR THR FGR CO 2/CO Residue/ Polymers, 2017, 175: 636-644.

样品 TTI/s 2 2 2

/(kW/m ) /(MJ/m ) /〔kW/(m ·s)〕/(kg/kg) % [10] XU Z Z, HUANG J Q, CHEN M J, et al. Flame retardant mechanism

纯棉 14.0 203.5 6.0 6.0 12.1 1.0 of an efficient flame-retardant polymeric synergist with ammonium

织物 polyphosphate for polypropylene[J]. Polymer Degradation and Stability,

2013, 98(10): 2011-2020.

整理 23.0 57.9 2.9 1.8 7.8 23.1

织物 (下转第 833 页)