Page 104 - 《精细化工》2020年第5期

P. 104

·954· 精细化工 FINE CHEMICALS 第 37 卷

从图 11 可以看出,喷洒水的煤样在振荡过程中 在此条件下制备的产品稳定性良好、成膜柔软、热

损失的煤粉量相较于喷洒阻燃抑尘剂的煤粉有非常 稳定性高。应用性能测试结果表明,该产品具有良

明显的差异,20 h 后经水处理的煤粉损失率达到 好的抑尘及阻燃性能,在实际应用中可以有效抑制

34.6%,喷洒市售抑尘剂的煤样吹蚀 3 h 后损失率为 煤尘污染及煤炭自燃,具有较好的应用前景。

4.3%,而经阻燃抑尘剂处理的煤粉 20 h 后损失率仅

参考文献:

为 1.4%,相较于水处理的煤样下降了 96.0%,较市

[1] XIE H P (谢和平), WU L X (吴立新), ZHENG D Z (郑德志).

售抑尘剂处理的煤样下降了 67.4%。因为喷洒抑尘

Prediction on the energy consumption and coal demand of China in

剂后煤粉被紧密的粘结在一起,形成一定强度的固 2025[J]. Journal of Coal (煤炭学报), 2019, 44(7): 1949-1960.

结层,从而在振荡过程中可以减缓煤粉的损失。由 [2] WU J (吴静), SONG X M (宋晓明), LIU S (刘硕), et al. Advances

in research on atmospheric particulate matter pollution and

此可见,该抑尘剂对煤粉的抗振荡性能有明显提高。

carcinogenesis in China[J]. Science and Technology Guide (科技导

报), 2018, 36(15): 32-38.

2.3.4 阻燃性能测试 [3] YANG S Y (杨树莹), ZHOU L (周磊), YANG L J (杨林军), et al.

以高温条件下排放的 CO 质量浓度作为阻燃效 Inhibition characteristics of polymer dust suppressants on fine

particles in brown coal mines[J]. Journal of Coal (煤炭学报), 2019,

果参考标准,测试结果如图 12 所示。

44(2): 528-535.

[4] HUANG Z A, LIU X H, GAO Y K, et al. Experimental study on the

compound system of proanthocyanidin and polyethylene glycol to

prevent coal spontaneous combustion[J/OL]. Fuel, 2019, 254:

1-10[2019-10-10]. https://doi.org/10.1016/j.fuel.2019.06.018.

[5] LIU G Q (刘国强). Self-ignition risk and prevention in open-pit coal

storage yard[J]. Fire Industry (消防界: 电子版), 2018, 4(14): 62.

[6] ZHANG X Y (张小艳). Effect of citric acid on coal spontaneous

combustion characteristics[D]. Beijing: China University of Mining

and Technology (中国矿业大学), 2019.

[7] GONZALEZ A, AITKEN D, HEITZER C, et al. Reducing mine

water use in arid areas through the use of a byproduct road dust

suppressant[J]. Journal of Cleaner Production, 2019, 230: 46-54.

[8] MEDEIROS M A, LEITE C M M, LAGO R M. Use of glycerol

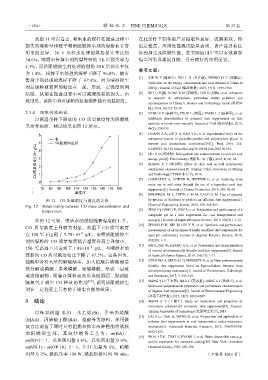

图 12 CO 质量浓度与温度的关系 by-product of biodiesel to produce an efficient dust suppressant[J].

Fig. 12 Relationship between CO mass concentration and Chemical Engineering Journal, 2012, 180: 364-369.

temperature [9] ZHOU G, DING J F, SUN J, et al. Preparation and performance of a

composite gel as a dust suppressant for coal transportation and

由图 12 可知,喷洒水的煤粉随着温度的上升, storage[J]. Journal of Applied Polymer Science, 2019, 136(31): 1-12.

[10] ZHANG H H, NIE W, LIU Y H, et al. Synthesis and performance

CO 质量浓度上升较为明显,高温下 CO 质量浓度

measurement of environment-friendly solidified dust suppressant for

–4

在 150 ℃下达到了 5.79×10 g/L,而喷洒阻燃抑尘 open pit coalmine[J]. Journal of Applied Polymer Science, 2018,

剂的煤粉的 CO 质量浓度随着温度升高上升较小, 135(29): 1-11.

[11] JIN H, NIE W, ZHANG H H, et al. Preparation and characterization

–4

150 ℃高温下只达到了 1.88×10 g/L,与喷洒水的

of a novel environmentally friendly coal dust suppressant[J]. Journal

煤粉的 CO 质量浓度相比下降了 67.5%。这是因为, of Applied Polymer Science, 2019, 136(17): 1-11.

植酸中含有大量的磷酸酯基,加入植酸后磷酸酯受 [12] VITOLINA S, SHULGA G, NEIBERTE B, et al. New environmentally

friendly dust suppressant based on lignocellulosic biomass from

热分解成磷酸、多聚磷酸、聚偏磷酸,形成一层玻 wood processing wastewater[J]. Journal of Environment, Technology

璃态熔融物,附着在煤粉表面形成阻隔层,起到阻 and Resources, 2017, 3: 343-349.

隔氧气并减少 CO 释放的作用 [26] 。说明该阻燃抑尘 [13] WANG Y H (王永慧), JIA Z C (贾志超), JIANG L T (蒋林天), et al.

Microwave polymerization preparation and performance characterization

剂在一定程度上具有防止煤尘自燃的效果。 of bagasse dust suppressant[J]. Journal of Environmental Engineering

(环境工程学报), 2017, 11(7): 4202-4209.

3 结论 [14] WANG Z Y (王振宇). Study on mechanism and properties of

microwave polymerized composite dust suppressant[D]. Taiyuan:

以环氧树脂 E-51、苯乙烯(St)、甲基丙烯酸 Taiyuan University of Technology (太原理工大学), 2019.

[15] LAI S L, CHAI Q, WANG B, et al. Preparation and application of

(MAA)、丙烯酸丁酯(BA)、植酸等为原料,采用微 polymer dust suppressants in coal transportation under microwave

波方法制备了同时具有阻燃和抑尘两种性能的软膜 irradiation[J]. Advanced Materials Research, 2012, 396/397/398:

型 阻 燃 抑尘剂 。其 较佳制 备工 艺为: m(BA) ∶ 1632-1635.

[16] WOO J T K, TING V, EVANS J, et al. Water dispersible epoxy-g-

m(St)=2∶1,引发剂用量 0.6%,乳化剂用量为 6%, acrylic copolymer for container coating[M]. New York: American

m(MS-1)∶m(OP-10)=2∶3,E-51 用量为 6%,植酸 Chemical Society, 1983: 283-300.

用量为 2%,微波功率 100 W,微波辐射时间 90 min。 (下转第 1023 页)