Page 136 - 《精细化工》2020年第8期

P. 136

·1634· 精细化工 FINE CHEMICALS 第 37 卷

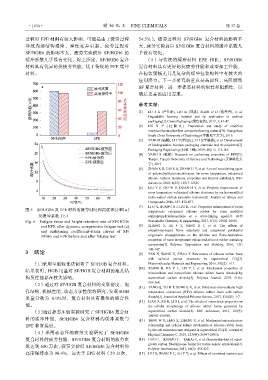

过程对 EPE 材料有较大影响,可能是由于疲劳过程 54.5%)。疲劳过程对 SF/HGB6 复合材料的影响不

导致内部结构塌陷,弹性变差引起。疲劳过程对 大,疲劳实验前后 SF/HGB6 复合材料的缓冲系数几

SF/HGB6 的影响不大,疲劳实验前后 SF/HGB6 的 乎没有变化。

缓冲系数几乎没有变化。综上所述,SF/HGB6 复合 (5)与传统的缓冲材料 EPE 相比,SF/HGB6

材料具有优异的抗疲劳性能,优于传统的 EPE 缓冲 复合材料具有更好的抗疲劳性能和成型加工性能,

材料。 在包装领域尤其是复杂的缓冲包装构件中有较大的

应用潜力。下一步研究的重点是高韧性、高阻燃型

SF 复合材料,进一步提高材料的韧性和阻燃性,以

满足更高的应用需求。

参考文献:

[1] LU J X (卢佳欣), LIU H (刘惠), SHEN D D (沈丹丹), et al.

Degradable foaming material and its application in cushion

packaging[J]. Green Packaging (绿色包装), 2017, 3: 41-47.

[2] DU X Y ( 杜新亚 ). Preparation and study of modified

montmorillonite-plant fiber composite foaming material[D]. Guangzhou:

South China University of Technology (华南理工大学), 2019.

[3] YANG P (杨鹏), LI J Y(李加友), LI J J(李娟娟), et al. Development

of biodegradable biomass packaging materials and its properties[J].

Packaging Engineering (包装工程), 2019, 40(11): 112-116.

[4] YANG S (杨帅). Research on cushioning properties of EPE[D].

Tianjin: Tianjin University of Science and Technology (天津科技大

学), 2015.

[5] ZHAN X B, CAI X Q, ZHANG J Y, et al. A novel crosslinking agent

of polymethyl(ketoxime)siloxane for room temperature vulcanized

silicone rubbers: Synthesis, properties and thermal stability[J]. RSC

Advances, 2018, 8(23): 12517-12525.

[6] LIU Y F, CHI W D, DUAN H Y, et al. Property improvement of

room temperature vulcanized silicone elastomer by surface-modified

multi-walled carbon nanotube inclusion[J]. Journal of Alloys and

Compounds, 2016, 657: 472-477.

[7] LI Q G, HUANG X J, LIU H, et al. Properties enhancement of room

图 6 SF/HGB6 及 EPE 材料的疲劳时间和高度保持率(a) temperature vulcanized silicone rubber by rosin modified

及缓冲系数(b) aminopropyltriethoxysilane as a cross-linking agent[J]. ACS

Fig. 6 Fatigue times and height retention rate of SF/HGB6 Sustainable Chemistry & Engineering, 2017, 5(11): 10002-10010.

and EPE after dynamic compressive fatigue test (a), [8] ZHANG Y, HE J Y, YANG R J, et al. The effects of

and cushioning coefficient-strain curves of SF/ phosphorus-based flame retardants and octaphenyl polyhedral

HGB6 and EPE before and after fatigue test oligomeric silsesquioxane on the ablative and flame-retardation

properties of room temperature vulcanized silicone rubber insulating

composites[J]. Polymer Degradation and Stability, 2016, 125:

140-147.

3 结论 [9] YAN H, WANG K, ZHAO Y. Fabrication of silicone rubber foam

with tailored porous structures by supercritical CO 2[J].

(1)采用室温硫化法制备了 SF/HGB 复合材料, Macromolecular Materials and Engineering, 2016, 302(2): 1-11.

[10] XIANG B, JIA Y L, LEI Y J, et al. Mechanical properties of

结果表明,HGB 用量对 SF/HGB 复合材料的泡孔结

microcellular and nanocellular silicone rubber foams obtained by

构及性能存在较大影响。 supercritical carbon dioxide[J]. Polymer Journal, 2019, 51(6):

559-568.

(2)通过对 SF/HGB 复合材料的交联密度、泡

[11] YANG Q, YU H T, SONG L X, et al. Solid-state microcellular high

孔结构、机械性能、动态力学性能的研究,发现 HGB temperature vulcanized (HTV) silicone rubber foam with carbon

质量分数为 6.0%时,复合材料具有最佳的综合性 dioxide[J]. Journal of Applied Polymer Science, 2017, 134(20): 1-7.

[12] LIAO X, XU H, LI S J, et al. The effects of viscoelastic properties on

能。 the cellular morphology of silicone rubber foams generated by

(3)通过静态压缩实验研究了 SF/HGB6 复合材 supercritical carbon dioxide[J]. RSC Advances, 2015, 129(5):

106981-106988.

料的缓冲性能,SF/HGB6 复合材料的缓冲系数与 [13] TANG W Y, LIAO X, ZHANG Y, et al. Mechanical-microstructure

EPE 非常接近。 relationship and cellular failure mechanism of silicone rubber foam

by the cell microstructure designed in supercritical CO 2[J]. Journal of

(4)采用动态压缩疲劳实验研究了 SF/HGB6

Physical Chemistry C, 2019, 123(44): 26947-26956.

复合材料的疲劳性能,SF/HGB6 复合材料的疲劳次 [14] GUO C, KONDO Y, TAKAI C, et al. Piezoresistivities of vapor-

grown carbon fiber/silicone foams for tactile sensor applications[J].

数达到 600 万次,疲劳实验后 SF/HGB6 复合材料的

Polymer International, 2017, 66(3): 418-427.

高度保持率为 98.4%,远大于 EPE 材料(29 万次, [15] LIU B, WANG P C, AO Y Y, et al. Effects of combined neutron and