Page 114 - 《精细化工》2020年第2期

P. 114

·316· 精细化工 FINE CHEMICALS 第 38 卷

CO 2 、N 2 )起到稀释易燃气体的作用,阻燃剂的加 (化工学报), 2013, 64(1): 182-197.

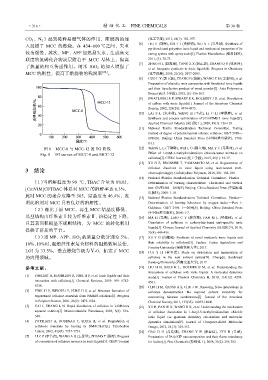

入延缓了 MCC 的燃烧。在 434~600 ℃之间,失重 [6] LIU H (刘晖), SHI T J (史铁钧), WU X L (吴星林). Synthesis of

pyridine-based polyether ionic liquid and mechanical properties of its

较为缓慢,其次,MP、APP 加热易失水,生成高交 curing system with epoxy resin[J]. Plastics Manufacture (塑料制造),

联度的氮磷化合物炭层附着于 MCC 基体上,隔离 2011, (3): 70-73.

[7] ZHAO H L (赵海丽), TANG Z X (汤正新), ZHANG Q G (张庆国),

了热量的相互传递作用。纳米 SiO 2 的加入增强了 et al. Inorganic synthesis in ionic liquids[J]. Progress in Chemistry

MCC 的刚性,提高了燃烧物的残炭率 [22] 。 (化学进展), 2009, 21(10): 2077-2083.

[8] GUO L Y (郭立颖), ZHANG B (张彬), WANG Z M (王志明), et al.

Preparation of phenolic resin composites with functional ionic liquids

and their liquefaction product of wood powder[J]. Acta Polymerica

Sinica (高分子学报), 2015, (5): 556-563.

[9] SWATLOSKI R P, SPEARP S K, HOLBREY J D, et al. Dissolution

of cellose with ionic liquids[J]. Journal of the American Chemical

Society, 2002, 124(18): 4974-4975.

[10] LAI S L (来水利), WANG H (王花), LI C H (李晨辉), et al.

Synthesis and process optimization of [CmVIM]Cl ionic liquid[J].

Applied Chemical Industry (应用化工), 2020, 49(1): 126-129.

[11] National Textile Standardization Technical Committee. Testing

method of degree of polymerization oframie cellulose: GB/T 5888—

1986[S]. Beijing: China Standard Press (中国标准出版社), 1986:

1-11.

图 8 MCC-0 与 MCC-12 的 TG 曲线 [12] WANG L L (王琳琳), WEI L G (魏立纲), MA Y C (马英冲), et al.

Fig. 8 TG curves of MCC-0 and MCC-12 Effect of 1-butyl-3-methylimidazolium chloride-water mixtures on

cellulose[J]. CIESC Journal (化工学报), 2015, 66(1): 32-37.

[13] XU H Z, BRONNER T, YAMAMOTO M, et al. Regeneration of

3 结论 cellulose dissolved in ionic liquid using laser-heated melt-

electrospinning[J]. Carbohydrate Polymers, 2018, 201: 182-188.

[14] National Plastics Standardization Technical Committee. Plastics—

(1)当溶解温度为 90 ℃,TBAC 含量为 8%时, Determination of burning characteristics—Horizontal and vertical

[CmVIM]Cl/TBAC 体系对 MCC 的溶解率达 6.3%, test: GB/T2408—2008[S]. Beijing: China Standard Press (中国标准

出版社), 2008: 1-18.

此时 MCC 的聚合度降至 505,结晶度为 46.4%,表 [15] National Plastics Standardization Technical Committee. Plastics—

明此溶剂对 MCC 具有良好的溶解性。 Determination of burning behaviour by oxygen index—Part 1:

(2)相比于原 MCC,再生 MCC 结晶度降低, Guidance: GB/T 2406. 1—2008[S]. Beijing: China Standard Press

(中国标准出版社), 2008: 1-7.

晶型结构由纤维素Ⅰ转为纤维素Ⅱ,热稳定性下降, [16] MA H (马浩), LIAO C Y (廖春燕), FAN M L (樊梅林), et al.

且其表面粗糙呈不规则结构,为 MCC 的转化利用 Dissolution of cellulose in carboxylate-based task-specific ionic

liquids[J]. Chinese Journal of Applied Chemistry (应用化学), 2018,

提供了崭新的平台。

35(4): 449-456.

(3)当 MP、APP、SiO 2 的质量分数分别为 5%、 [17] XU Y G (许耀光). Synthesis of novel imidazole ionic liquids and

10%、10%时,阻燃纤维素复合材料的阻燃效果最佳, their solubility to cellulose[D]. Fuzhou: Fujian Agriculture and

Forestry University (福建农林大学), 2017.

LOI 为 33.5%,垂直燃烧等级为Ⅴ-0,拓宽了 MCC [18] CUI Y H (崔玉虎). Study on dissolution and regeneration of

的应用领域。 cellulose in the new solvent system[D]. Chengdu: Southwest

Jiaotong University (西南交通大学), 2017.

参考文献: [19] LIU H B, SALE K L, HOLMES B M, et al. Understanding the

interactions of cellulose with ionic liquids: A molecular dynamics

[1] PINKERT A, HEUBLEIN B, FINK H P, et al. Ionic liquids and their study[J]. Journal of Physical Chemistry B, 2010, 114(12): 4293-

interaction with cellulose[J]. Chemical Reviews, 2009, 109: 6712- 4301.

6728. [20] CHO H M, GROSS A S, CHU J W. Dissecting force interactions in

[2] FINK H P, WEIGELl P, PURZ H J, et al. Structure formation of cellulose deconstruction the required solvent versatility for

regenerated cellulose materials from NMMO-solutions[J]. Progress overcoming biomass recalcitrance[J]. Journal of the American

in Polymer Science, 2001, 26(9): 1473-1524. Chemical Society, 2011, 133(35): 14033-14041.

[3] CAI J, ZHANG L N. Rapid dissolution of cellulose in LiOH/urea [21] XU H, PAN W X, WANG R X, et al. Understanding the mechanism

aqueous solution[J]. Macromolecular Bioscience, 2005, 5(6): 539- of cellulose dissolution in 1-butyl-3-methylimidazolium chloride

548. ionic liquid via quantum chemistry calculations and molecular

[4] POTTHAST A, ROSENAU T, SIXTA H, et al. Degradation of dynamics simulations[J]. Journal of Computer-Aided Molecular

cellulosic materials by heating in DMAC/LiCl[J]. Tetrahedron Design, 2012, 26 (3): 329-337.

Letters, 2002, 43(43): 7757-7759. [22] GAO D G (高党鸽), ZHANG Y H (张亚红), LYU B (吕斌).

[5] LI C Z (李昌志), WANG A Q (王爱琴), ZHANG T (张涛). Progress Preparation of PAA/ATP nanocomposites and their flame retardancy

of conversion of cellulose resource in ionic liquids[J]. CIESC Journal for leather[J]. Fine Chemicals (精细化工), 2018, 35(2): 298-302.