Page 173 - 《精细化工》2021年第6期

P. 173

第 6 期 高党鸽,等: 含氨基和羧基 POSS/聚合物复合材料鞣制性能 ·1235·

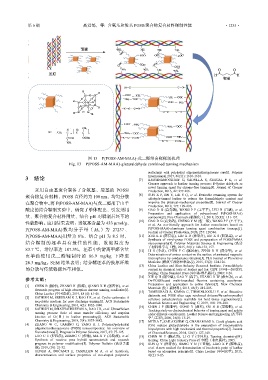

图 13 P(POSS-AM-MAA)-戊二醛结合鞣鞣制机理

Fig. 13 P(POSS-AM-MAA)-glutaraldehyde combined tanning mechanism

surfactants with polyhedral oligomericsilsesquioxane core[J]. Polymer

3 结论 [7] International, 2017, 66(11): 1610-1616.

KRISHNAMOORTHY G, SADULLA S, SEHGAL P K, et al.

Greener approach to leather tanning process: D-lysine aldehyde as

novel tanning agent for chrome-free tanning[J]. Journal of Cleaner

采用自由基聚合制备了含氨基、羧基的 POSS/ Production, 2013, 42: 277-286.

聚合物复合材料,POSS 直径约为 100 nm,均匀分散 [8] SUN X P, JIN Y, LAI S Q, et al. Desirable retanning system for

aldehyde-tanned leather to reduce the formaldehyde content and

在聚合物中。将 P(POSS-AM-MAA)与戊二醛用于山羊 improve the physical-mechanical properties[J]. Journal of Cleaner

Production, 2018, 175: 199-206.

酸皮的结合鞣制实验中,研究了单体配比、引发剂用 [9] GAO D G (高党鸽), WANG P P (王平平), LYU B (吕斌), et al.

Preparation and application of polycarboxyl P(POSS-MAA)

量、聚合物复合材料用量、结合 pH 对鞣制后坯革的 composite[J]. Fine Chemicals (精细化工), 2018, 35(12): 131-137.

[10] GAO D G (高党鸽), CHENG Y M (程一铭), WANG P P (王平平),

性能影响。应用结果表明:当氨基含量为 433 μmol/g、 et al. An eco-friendly approach for leather manufacture based on

P(POSS-AM-MAA) 数均分子量(M n )为 27237、 P(POSS-MAA)-aluminum tanning agent combination tannage[J].

Journal of Cleaner Production, 2020, 257: 120546.

P(POSS-AM-MAA)用量为 8%、结合 pH 为 8.5 时, [11] XUE L Z (薛亮忠), LIN X D (林晓丹), HU X S (胡新嵩), et al.

Synthesis of vinyl-group POSS and poreparation of POSS/PMMA

结合鞣制的坯革具有最佳的性能,收缩温度为 nanocomposite[J]. Polymer Materials Science & Engineering (高分

子材料科学与工程), 2015, 31(1): 148-152, 157.

83.7 ℃,增厚率达 107.3%,坯革中的游离甲醛含量 [12] LI S (李双), CHEN F C (陈风春), ZENG R H (曾荣华), et al.

由单独使用戊二醛鞣制时的 86.9 mg/kg 下降至 Determination of amino content on the surface of aminated magnetic

microspheres by conductance titration[J]. PLA Journal of Preventive

28.3 mg/kg。SEM 结果表明:结合鞣坯革的胶原纤维 Medicine (解放军预防医学杂志), 2015, 33(2): 124-126.

[13] China Leather and Shoe Industry Research Institute. Formaldehyde

的分散与传统铬鞣坯革相似。 content in chemical tests of leather and fur: GB/T 19941—2005[S].

Beijing: China Standard Press (中国标准出版社), 2005: 9-26.

[14] XIE Q H (谢全焕), GAO Y (高宇), ZHANG D W (张大为), et al.

参考文献: Ov-POSS-based multi-branched fluorine containing copolymer:

Preparation and application to cotton fabrics[J]. New Chemical

[1] CHEN B (陈博), ZHANG H (张辉), QIANG X H (强西怀), et al. Materials (化工新材料), 2015, 43(3): 212-215.

Research progress of high absorption chrome tanning auxiliaries[J]. [15] TAMBURACI S, KIMNA C, TIHMINLIOGLU F, et al. Bioactive

China Leather (中国皮革), 2019, 48 (4): 41-46.

[2] SATHISH M, SREERAM K J, RAO J R, et al. Cyclic carbonate: A diatomite and POSS silica cage reinforced chitosan/Na-carboxymethyl

cellulose polyelectrolyte scaffolds for hard tissue regeneration[J].

recyclable medium for zero discharge tanning[J]. ACS Sustainable Materials Science and Engineering: C, 2019, 100: 196-208.

Chemistry & Engineering, 2016, 4(3): 1032-1040. [16] CHEN J P (陈继平), GONG Y (龚英), GU H B (辜海彬), et al.

[3] SATHISH M, DHATHATHREYAN A, RAO J R, et al. Ultraefficient Tracking study on electrochemical behavior of tanning agent and gelatin

tanning process: Role of mass transfer efficiency and sorption under different conditions[J]. Leather Science and Engineering (皮革科

kinetics of Cr( Ⅲ ) in leather processing[J]. ACS Sustainable 学与工程), 2006, 16(6): 15-19.

Chemistry & Engineering, 2019, 7(4): 3875-3882. [17] MITRA T, SAILAKSHMI G, GNANAMANI A. Could glutaric acid

[4] ZHANG W C, CAMINO G, YANG R J. Polymer/polyhedral (GA) replace glutaraldehyde in the preparation of biocompatible

oligomericsilsesquioxane (POSS) nanocomposites: An overview of biopolymers with high mechanical and thermal properties[J]. Journal

fire retardance[J]. Progress in Polymer Science, 2017, 67: 77-125. of Chemical Sciences, 2014, 126(1): 127-140.

[5] LUO C C (罗程晨), ZHANG C (张驰), MA X Y (马晓燕), et al. [18] CHEN W Y (陈武勇), LI G Y (李国英). Tanning chemistry[M].

Synthesis of reactive poss hybrid nanomaterials and research Beijing: China Light Industry Press (中国轻工业出版社), 2005.

progress in polymer modification[J]. Polymer Bulletin (高分子通 [19] SUN Q Y (孙青永), WANG Y N (王亚楠), LIAO X P (廖学品),

报), 2019, (10): 21-32. et al. A new method for determination of isoelectric point of leather

[6] UENER A, DOČANCI E, TASDELEN M A, et al. Synthesis, based on adsorption principle[J]. China Leather (中国皮革), 2013,

characterization and surface properties of star-shaped polymeric 42(1): 9-13.