Page 207 - 《精细化工》2021年第11期

P. 207

第 11 期 牛 静,等: 微米级 P-Si@a-TiO 2 负极材料的制备及电化学性能 ·2353·

silicon electrodes for lithium-ion batteries[J]. Journal of Power

Sources, 2020, 454: 227907.

[4] ZHU C Y, ZHANG Y, MA Z H, et al. Yolk-void-shell Si-C nano-

particles with tunable void size for high-performance anode of

lithium ion batteries[J]. Nanotechnology, 2021, 32(8): 085403.

[5] XIE J, TONG L, SU L W, et al. Core-shell yolk-shell Si@C@void@C

nanohybrids as advanced lithium ion battery anodes with good

electronic conductivity and corrosion resistance[J]. Journal of Power

Sources, 2017, 342: 529-536.

[6] CHEN X D (陈修栋), YAN P (严平), LIU J H (刘金杭), et al.

Preparation and electrochemical performances of granular nickel

molybdate anode material[J]. Fine Chemical (精细化工), 2021,

38(3): 554-558.

[7] CHEN J J, LU X Y, SUN J, et al. Si@C nanosponges application

for lithium ions batteries synthesized by templated magnesiothermic

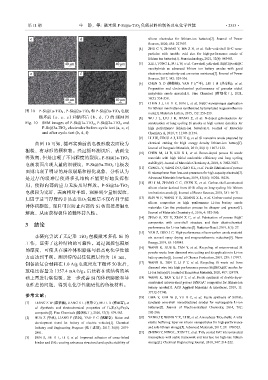

图 10 P-Si@1a-TiO 2 、P-Si@2a-TiO 2 和 P-Si@3a-TiO 2 电极

route[J]. Materials Letters, 2015, 152: 256-259.

循环前(a、c、e)和循环后(b、d、f)的 SEM 图 [8] WU J L, LIU J H, WANG Z, et al. N-doped gel-structures for

Fig. 10 SEM images of P-Si@1a-TiO 2 , P-Si@2a-TiO 2 and construction of long cycling Si anodes at high current densities for

P-Si@3a-TiO 2 electrodes before cycle test (a, c, e) high performance lithium-ion batteries[J]. Journal of Materials

and after cycle test (b, d, f) Chemistry A, 2019, 7: 11347-11354.

[9] LI J W, ZHOU A J, LIU X Q, et al. Si nanowire anode prepared by

由图 10 可知,循环实验前的电极形貌表面较为 chemical etching for high energy density lithium-ion battery[J].

Journal of Inorganic Materials, 2013, 28(11): 1207-1212.

粗糙,有球形的颗粒物。经过循环测试后,表面变

[10] CHEN M, LI B, LIU X J, et al. Boron-doped porous Si anode

得致密,但是出现了不同程度的裂纹。P-Si@1a-TiO 2 materials with high initial coulombic efficiency and long cycling

电极表面出现大量的细裂纹,P-Si@3a-TiO 2 电极表 stability[J]. Journal of Materials Chemistry A, 2018, 6: 3022-3027.

[11] GENG L Y, YANG D D, GAO S L, et al. Facile fabrication of porous

面则出现了明显的局部崩塌和粉化现象,分析认为 Si microspheres from low-cost precursors for high-capacity electrode[J].

是过厚的缓冲层使得多孔结构不能更好地发挥作 Advanced Materials Interfaces, 2019, 43(46): 18220-18228.

[12] SU J M, ZHANG C C, CHEN X, et al. Carbon-shell-constrained

用,使得内部的应力无法及时释放。P-Si@2a-TiO 2

silicon cluster derived from Al-Si alloy as long-cycling life lithium

电极较为完好,表面相对平坦,观察到少量细裂纹, ion batteries anode[J]. Journal of Power Sources, 2018, 381: 66-71.

归因于适当厚度的非晶态 TiO 2 包覆层不仅有利于缓 [13] REN W F, WANG Y H, ZHANG Z L, et al. Carbon-coated porous

silicon composites as high performance Li-ion battery anode

冲体积膨胀,而且可以防止内部的 Si 核直接接触电 materials: Can the production process be cheaper and greener[J].

解液,从而获得极佳的循环持久性。 Journal of Materials Chemistry A, 2016, 4: 552-560.

[14] ZHAO S, XU Y, XIAN X C, et al. Fabrication of porous Si@C

3 结论 composites with core-shell structure and their electrochemical

performance for Li-ion batteries[J]. Batteries-Basel, 2019, 5(1): 27.

[15] YAN Z, GUO J C. High-performance silicon-carbon anode material

本研究尝试了无定形 TiO 2 包覆微米多孔 Si 的 via aerosol spray drying and magnesiothermic reduction[J]. Nano

工作,证实了这种结构的可靠性。通过调控包覆层 Energy, 2019, 63: 103845.

[16] WANG K, XUE B, TAN Y, et al. Recycling of micron-mized Si

的厚度,可使其在缓冲体积膨胀与提高电化学性能

powder waste from diamond wire cutting and its application in Li-ion

方面达到平衡。测所得的最佳包覆层约为 10 nm, battery anodes[J]. Journal of Cleaner Production, 2019, 239: 117997.

制备的复合材料在 1.0 A/g 电流密度下循环 50 次后, [17] WANG K, TAN Y, LI P T, et al. Recycling Si waste cut from

diamond wire into high performance porous Si@SiO 2@C anodes for

放电比容量为 1357.4 mA·h/g。后续将在该结构的基 Li-ion battery[J]. Journal of Hazardous Materials, 2020, 407: 124778.

础上再进行碳包覆,进一步改善 Si 的体积膨胀和导 [18] WANG K, TAN Y, LI P T, et al. Facile synthesis of double-layer-

constrained micron-sized porous Si/SiO 2/C composites for lithium-ion

电性差的问题,得到电化学性能更优的负极材料。

battery anodes[J]. ACS Applied Materials & Interfaces, 2019, 11:

37732-37740.

参考文献: [19] HWA Y, KIM W S, YU B C, et al. Facile synthesis of Si/TiO 2

[1] LIANG Z W (梁紫薇), JIANG R L (蒋荣立), MU L X (穆丽雪), et (anatase) core-shell nanostructured anodes for rechargeable Li-ion

al. Synthesis and electrochemical properties of Li 4Ti 5O 12/Fe 3O 4 batteries[J]. Journal of Electroanalytical Chemistry, 2014, 712:

composite[J]. Fine Chemicals (精细化工), 2020, 37(3): 579-583. 202-206.

[2] HUA Z (华政), LIANG F (梁风), YAO Y C (姚耀春). Status and [20] YANG J P, WANG Y X, LI W, et al. Amorphous TiO 2 shells: A vital

development trend for battery of electric vehicles[J]. Chemical elastic buffering layer on silicon nanoparticles for high-performance

Industry and Engineering Progress (化工进展), 2017, 36(8): 2874- and safe lithium storage[J]. Advanced Materials, 2017, 29: 1700523.

2881. [21] ZHENG Y, NING L, XUN T J, et al. TiO 2 coated Si/C interconnected

[3] SUN S, HE D L, LI P, et al. Improved adhesion of cross-linked microsphere with stable framework and interface for high-rate lithium

binder and SiO 2-coating enhances structural and cyclic stability of storage[J]. Chemical Engineering Journal, 2018, 347: 214-222.