Page 231 - 《精细化工》2023年第9期

P. 231

第 9 期 朱港港,等: 桐油酸改性含环氧基团聚丙烯酸酯乳液的制备 ·2079·

resins: Synthesis principle, modification strategies, and their applications[J].

ACS Omega, 2021, 6(4): 2443-2449.

[2] FAN X, XIA Y, WU S, et al. Covalently immobilization of modified

graphene oxide with waterborne hydroxyl acrylic resin for anticorrosive

reinforcement of its coatings[J]. Progress in Organic Coatings: An

International Review Journal, 2022, 163: 106685.

[3] ZHANG C (张琛). Synthesis and property of waterborne epoxy/

acrylic composite latex and anti-corrosion coation[D]. Beijing:

Beijing University of Chemical Technology (北京化工大学), 2016.

[4] PENG J (彭军), YANG Y N (杨育农), XIE Y F (谢宇芳). Synthesis

and properties of waterborne epoxy self-crosslinking acrylic resin[J].

Coating and Protection (涂层与防护), 2021, 42(4): 48-53.

[5] LIU X Q (刘新迁), TU X H (屠晓华), XU Y Y (徐欣欣), et al.

Synthesis of high solid carboxylate/sulfonate waterborne polyurethane

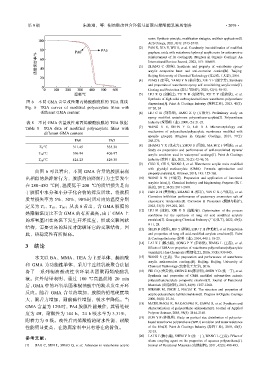

图 6 不同 GMA 含量改性聚丙烯酸酯胶膜的 TGA 曲线 dispersions[J]. Paint & Coatings Industry (涂料工业), 2013, 43(3):

Fig. 6 TGA curves of modified polyacrylate films with 17-20, 24

different GMA content [6] LIU C H (刘春华), FANG Z Q (方治齐). Preliminary study on

epoxy modified waterborne polyurethane-acrylate[J]. Polyurethane

表 8 不同 GMA 含量改性聚丙烯酸酯胶膜的 TGA 数据 Industry (聚氨酯工业), 2000, (3): 21-23.

Table 8 TGA data of modified polyacrylate films with [7] WANG X R, SHEN Y D, LAI X J. Micromorphology and

different GMA content mechanism of polyurethane/polyacrylate membranes modified with

epoxide group[J]. Progress in Organic Coatings, 2014, 77(1):

PA0 PA5 268-276.

T 5/℃ 311.45 333.38 [8] ZHANG Y X (张永兴), ZHOU S (周晟), MA M Z (马明珠), et al.

Study on preparation and performance of self-crosslinked styrene/

T 50/℃ 396.94 406.97 acrylic emulsion used in waterproof coatings[J]. Paint & Coatings

T 90/℃ 424.23 429.35 Industry (涂料工业), 2021, 51(2): 42-46, 53.

[9] GUO X, GE S, WANG J, et al. Waterborne acrylic resin modified

由图 6 可以看出,不同 GMA 含量的胶膜表现 with glycidyl methacrylate (GMA): Formula optimization and

property analysis[J]. Polymer, 2018, 143: 155-163.

出相似的热降解行为,胶膜的热降解行为主要发生 [10] WANG X W (王晓雯). Preparation and application of functional

acrylate latex[J]. Chemical Industry and Engineering Progress (化工

在 280~450 ℃间,温度低于 200 ℃的质量损失是由 进展), 2012, 31(9): 2011-2018.

于胶膜中水分和小分子化合物的挥发所致。将胶膜 [11] FAN Z H (樊治海), ZHANG H (张宏), YIN C X (尹成先), et al.

Corrosion inhibition performance of quaternary ammonium salt of

质量损失率为 5%、50%、90%时所对应的温度分别 elaeostearic imidazoline[J]. Corrosion & Protection (腐蚀与防护),

定义为 T 5 、T 50 、T 90 ;从表 8 看出,含 GMA 胶膜的 2012, 33(3): 199-201, 205.

[12] LIU H (刘宏), XIE G R (谢桂容). Optimization of the process

热降解温度比不含 GMA 的有所提高。由于 GMA 上 conditions for the synthesis of tung oil acid modified acrylate

的环氧基团在高温下发生开环反应,形成交联网状 emulsion[J]. Guangdong Chemical Industry (广东化工), 2022, 49(2):

9-11, 28.

结构,需要更高的温度才能破坏它的交联结构,因 [13] SHEN D (沈答), MU Y (穆颖), ZHU Y H (朱艳虹), et al. Preparation

此,热稳定性有所提高。 and properties of tung oil acid-modified acrylate emulsion[J]. Paint

& Coatings Industry (涂料工业), 2014, 44(1): 18-23.

[14] LAI X J (赖小娟), SONG P Y (宋沛艳), WANG L (王磊), et al.

3 结论 Effects of GMA on properties of waterborne polyurethane/polyacrylate

varnish[J]. Fine Chemicals (精细化工), 2016, 33(8): 939-945.

本文以 BA、MMA、HEA 为主要单体,桐油酸 [15] WANG S (王尚). The preparation and performance of waterborne

acrylic anticorrosion coatings[D]. Beijing: Beijing University of

和 GMA 为功能性单体,采用半连续乳液聚合法制 Chemical Technology (北京化工大学), 2016.

备了一系列桐油酸改性含环氧基团聚丙烯酸酯乳 [16] FEI G Q (费贵强), CHEN Z M (陈宗明), SHEN Y D (沈一丁), et al.

Synthesis and properties of GMA modified solvent-free anionic

液。红外结果表明,通过 180 ℃高温烘烤 20 min polyurethane/acrylate composite emulsion[J]. Journal of Functional

后,GMA 中的环氧基团和桐油酸中的羧基发生开环 Materials (功能材料), 2013, 44(9): 1257-1260.

[17] HIROSE M, ZHOU J, NAGAI K. The structure and properties of

反应。随着 GMA 含量的增加,胶膜的铅笔硬度增 acrylic-polyurethane hybrid emulsions[J]. Progress in Organic Coatings

大,附着力增加,耐酸碱性增强,吸水率降低。当 2000, 38(1): 27-34.

[18] MATSUNAGA K, NAKAGAWA K, SAWAI S, et al. Synthesis and

GMA 含量为 12%时,PA4 胶膜性能最佳,其铅笔硬 characterization of polyurethane anionomers[J]. Journal of Applied

度为 4H,耐酸性为 144 h,24 h 吸水率为 3.31%, Polymer Science, 2005, 98(5): 2144-2148.

[19] SUN Y P (孙艳璞). Study on partical size distribntion of polyester-

附着力为 0 级。改性后丙烯酸酯的耐水性能、耐酸 based waterborne polyurethane (WPU) emulsion and water resistance

性能明显提高,在防腐涂料中具有潜在的价值。 of the film[J]. Paint & Coatings Industry (涂料工业), 2010, 40(3):

32-35.

[20] LAI X J (赖小娟), SHEN Y D (沈一丁), WANG L (王磊). Effect of

参考文献:

silane coupling agent on the properties of aqueous polyurethane[J].

[1] JIAO C, SUN L, SHAO Q, et al. Advances in waterborne acrylic Journal of Functional Materials (功能材料), 2011, 42(3): 490-493.