Page 148 - 201811

P. 148

·1934· 精细化工 FINE CHEMICALS 第 35 卷

参考文献:

[1] Dufresne A, Castano J. Polysaccharide nanomaterial reinforced

starch nanocomposites: a review[J]. Starch-Stärke, 2016, 68(1/2):

1-19.

[2] Wang Kangjian (王康建), Dan Weihua (但卫华), Guan Linbo (关林

波 ), et al. Application of modified starch in leather-making

industry[J]. Leather Science and Engineering (皮革科学与工程),

2007, 17(6): 36-39.

[3] Jayakumar G C, Kanth S V, Rao J R, et al. A molecular level

investigation of dialdehyde starch interaction with collagen for

Eco-friendly stabilization[J]. Journal of the American Leather

Chemists Association, 2015, 110(5): 145-151.

[4] Kanth S V, Madhan B, Rao J R, et al. Studies on the stabilization of

collagen using dialdehyde starch: Part I. Effect of autoclaving on

dialdehyde starch[J].Journal of the American Leather Chemists

Association, 2006, 101(12): 444-453.

[5] Yuan Hongchang (袁鸿昌), Yang Mao (杨茂), Shan Zhihua (单志

华), et al. Advanced modification of soluble starch and its filling of

wet-chromed goat skin[J]. Fine Chemials(精细化工), 2014, 31(2):

229-233.

[6] Du X S, Chen H, Dai R, et al. Preparation and application of

denatured starches[J]. Journal of the Society of Leather

Technologises and Chemists, 2012, 96(5): 189-194.

[7] Wang Xuechuan (王学川), Li Feihu (李飞虎), Qiang Taotao (强涛

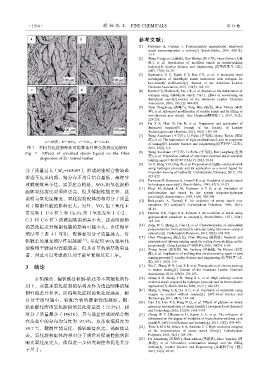

a—对照;b—WO 4;c—VO 3;d—Cu-Fe 涛), et al. The preparation of high-oxidized starch and its properties

of tannage[J]. Leather Science and Engineering(皮革科学与工程),

图 7 不同氧化淀粉配体对锆鞣革纤维分散程度的影响 2013, 23(2): 5-8.

Fig. 7 Effects of oxidized starch ligand on the fiber [8] Wang Xuechuan (王学川), Li Feihu (李飞虎), Ren Longfang (任龙

dispersion of Zr- tanned leather 芳), et al. Preparation method of aluminum-oxidized starch complex

tanning agent: CN102747173A [P]. 2012-10-24.

[9] Yu Y, Wang Y N, Ding W, et al. Preparation of highly-oxidized starch

using hydrogen peroxide and its application as a novel ligand for

分子质量过大(M w =465095),形成的锆配合物较难 zirconium tanning of leather[J]. Carbohydrate Polymers, 2017, 174:

渗透至皮革内部,锆分布不均且结合量低,最终导 823-829.

[10] Parovuori P, Hamunen A, Forssell P, et al. Oxidation of potato starch

致鞣制效果不佳。需要注意的是,WO 4 组氧化淀粉 by hydrogen peroxide[J]. Starch-Stärke, 1995, 47(1): 19-23.

[11] Floor M, Schenk K M, Kieboom A P G, et al. Oxidation of

配体氧化度比对照组更高,但其鞣制性能更差,这 maltodextrins and starch by the system tungstate-hydrogen

peroxide[J]. Starch-Stärke, 1989, 41(8): 303-309.

说明与氧化度相比,氧化淀粉配体的相对分子质量 [12] Bala-piaske A, Tomasik P. Air oxidation of potato starch over

对于鞣制性能的影响更大。另外,VO 3 组(氧化主 vanadium (V) catalyst[J]. Carbohydrate Polymers, 1999, 38(1):

41-45.

要发生于 C-6 位)和 Cu-Fe 组(氧化发生于 C-2、 [13] Harmon R E, Gupta S K, Johnson J. Air-oxidation of starch using

quinquevalent vanadium as catalyst[J]. Starch-Stärke, 1971, 23(4):

C-3 和 C-6 位)的鞣制效果相差不大,这表明淀粉 125-128.

的氧化位点对鞣制性能的影响可能不大。由锆鞣革 [14] Zeng W C, Zhang Z, Gao H, et al. Characterization of antioxidant

polysaccharides from auricularia auricular using microwave-assisted

增厚率(表 4)可知,配体相对分子质量越大,对 extraction[J]. Carbohydrate Polymers, 2012, 89(2): 694-700.

[15] Chen Zhanguang (陈占光), Chen Wuyong (陈武勇). Research and

锆鞣革的填充增厚作用越强 [23] 。考虑到 WO 4 组氧化 preparation of chrome tanning agent for cutting down pickling and its

properties[J]. China Leather (中国皮革), 2001, 30(23): 6-10.

淀粉用于鞣制时性能较差,但其对革的增厚效果显 [16] Zhang Jinwei (张金伟), Wu Jiacheng (吴佳城), Fu Meimei (付美

梅), et al. Application of pickling-free chrome tanning agent in post

著,因此可以考虑将其用于制革复鞣填充工序。

tanning process[J]. Leather Science and Engineering (皮革科学与工

程), 2014, 24(5): 5-9.

3 结论 [17] Wu C, Zhang W H, Liao X P, et al. Transposition of chrome tanning

in leather making[J]. Journal of the American Leather Chemists

Association, 2014, 109(6): 176-183.

在钨酸盐、偏钒酸盐和铜-铁盐等不同催化剂作 [18] Zhang S D, Zhang Y R, Wang X L, et al. High carbonyl content

oxidized starch prepared by hydrogen peroxide and its thermoplastic

用下,双氧水氧化淀粉的结构及作为锆盐配体的鞣 application[J]. Starch-Stärke, 2009, 61(11): 646-655.

[19] Sheng Y, Wang Q H, Xu X C, et al. Oxidation of cornstarch using

制性能差异显著。所得氧化淀粉的氧化度越高,相 oxygen as oxidant without catalyst[J]. LWT-Food Science and

对分子质量越小,锆配合物的鞣制性能越好。铜- Technology, 2011, 44(1): 139-144.

[20] Guo J J, Lian X J, Kang H Q, et al. Effects of glutenin in wheat

铁盐催化所得氧化淀粉的氧化度最高(72.5%),相 gluten on retrogradation of wheat starch[J]. European Food Research

and Technology, 2016, 242(9): 1485-1494.

对分子质量最小(14628),其与锆盐形成的配合物 [21] Chong W T, Uthumporn U, Karim A A, et al. The influence of

ultrasound on the degree of oxidation of hypochlorite-oxidized corn

在皮革中的分布均匀度为 97.8%,皮革收缩温度为 starch[J]. LWT-Food Science and Technology, 2013, 50(2): 439-443.

89.7 ℃,鞣制性能最优,偏钒酸盐次之,钨酸盐最 [22] Thire R M S M, Simao R A, Andrade C T. High resolution imaging

of the microstructure of maize starch films[J]. Carbohydrate

差。氧化淀粉配体的相对分子质量对鞣制性能的影 Polymers, 2003, 54(2): 149-158.

[23] Du Xiaosheng (杜晓声), Shan Zhihua (单志华), Zhou Yanchao (周

响比氧化度更大,值得进一步研究调控和优化其分 燕超 ), et al. Circulative combination tannage and the filling

method[J]. Leather Science and Engineering (皮革科学与工程),

子尺寸。 2013, 23(6): 26-29.