Page 89 - 201812

P. 89

第 12 期 孙培永,等: 脂肪酸甲酯加氢脱氧和加氢脱氮制备生物烷烃 ·2057·

在优化的反应条件下,生物烷烃加氢脱氮得到 paraffin emulsions used in the manufacture of chipboard panels by

liquid crystalline phases [J]. J Dispers Sci Technol, 2007, 28(6): 829-836.

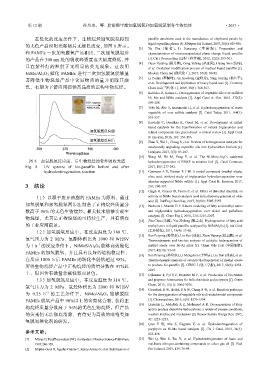

的无色产品经阳光曝晒后无颜色改变,如图 8 所示。

[3] Xu Zhe ( 徐哲 ), Li Jianqiang ( 李建强 ). Preparation and

和 FAMEs 一次加氢脱氧产品相比,二次加氢脱氮后 characterization of microencapsulated phase change liquid paraffin

的产品在 308 nm 处的吸收峰强度也大幅度降低,并 [J]. Chi J Process Eng (过程工程学报), 2012, 12(2): 293-301.

[4] Duan Yueying (段月英), Cong Yufeng (丛玉凤), Huang Wei (黄玮),

且在紫外灯的照射下无明显的荧光现象。这表明 et al. Oxidation modification process of medical liquid paraffin [J].

NiMo/Al 2 O 3 催化 FAMEs 进行二次加氢脱氮能够显 Modern Chem Ind (现代化工), 2017, 37(4): 80-82.

著降低生物烷烃产品中含氮物质的量并消除其颜 [5] Li Peijun (李佩均), Jin Xiaolong (金晓龙), Yang Jiuping (杨久平),

et al. Development and application of heavy liquid wax [J]. Contemp

色,有望为下游应用提供高品质的正构生物烷烃。 Chem Ind (当代化工), 2009, 38(4): 364-367.

[6] Kubicka D, Kaluza L. Deoxygenation of vegetable oils over sulfided

Ni, Mo and NiMo catalysts [J]. Appl Catal A: Gen, 2010, 372(2):

199-208.

[7] Toba M, Abe Y, Kuramochi H, et al. Hydrodeoxygenation of waste

vegetable oil over sulfide catalysts [J]. Catal Today, 2011, 164(1):

533-537.

[8] Kordulis C, Bourikas K, Gousi M, et al. Development of nickel

based catalysts for the transformation of natural triglycerides and

related compounds into green diesel: a critical review [J]. Appl Catal

B: Environ, 2016, 181: 156-196.

[9] Zhao X, Wei L, Cheng S, et al. Review of heterogeneous catalysts for

catalytically upgrading vegetable oils into hydrocarbon biofuels [J].

Catalysts, 2017, 7(3): 83-107.

[10] Wang M, He M, Fang Y, et al. The Ni-Mo/γ-Al 2O 3 catalyzed

图 8 加氢脱氮反应前、后生物烷烃的紫外吸收光谱 hydrodeoxygenation of FAME to aviation fuel [J]. Catal Commun,

Fig. 8 UV spectra of bio-paraffin before and after 2017, 100: 237-241.

hydrodenitrogenation reaction [11] Coumans A E, Hensen E J M. A model compound (methyl oleate,

oleic acid, triolein) study of triglycerides hydrodeoxygenation over

alumina-supported NiMo sulfide [J]. Appl Catal B: Environ, 2017,

3 结论 201: 290-301.

[12] Ojagh H, Creaser D, Tamm S, et al. Effect of dimethyl disulfide on

(1) 以源于废弃油脂的 FAMEs 为原料,通过 activity of NiMo based catalysts used in hydrodeoxygenation of oleic

acid [J]. Ind Eng Chem Res, 2017, 56(19): 5547-5557.

加氢脱氧和加氢脱氮两步法制备了正构烷烃质量分 [13] Hachemi I, Murzin D Y. Kinetic modeling of fatty acid methyl esters

数高于 96% 的无色生物烷烃。相关技术能够实现生 and triglycerides hydrodeoxygenation over nickel and palladium

catalysts [J]. Chem Eng J, 2018, 334: 2201-2207.

物烷烃,尤其是正构烷烃的可持续生产,具有潜在

[14] Zhu Chao (朱超), Yao Zhilong (姚志龙). Hydrogenation of fatty acid

的工业应用前景。 methyl ester to liquid paraffin catalyzed by Ni/NiAl 2O 4 [J]. Ind Catal

(2)加氢脱氧反应中,在反应温度为 380 ℃、 (工业催化), 2011, 19(4): 57-60.

[15] Sun Peiyong (孙培永), Liu Sen (刘森), Zhou Yupeng (周玉鹏), et al.

氢气压力为 2 MPa、氢酯体积比为 1000 和 WHSV Thermodynamic and kinetics analysis of catalytic hydrogenation of

–1

为 1 h 的反应条件下,NiMoS/Al 2 O 3 能够高效催化 methyl oleate over Ni-Al alloy [J]. China Oils Fats (中国油脂),

2017, 42(10): 93-99.

FAMEs 的加氢脱氧,并且具有良好的结构稳定性,

[16] Sun Peiyong (孙培永), Li Mengchen (李梦晨), Liu Sen (刘森), et al.

在反应 1000 h 后 FAMEs 的转化率仍然超过 98%。 Thermodynamic analysis of catalytic hydrogenation of methyl oleate

所得生物烷烃产品中正构烷烃的质量分数在 97%以 to produce bio-paraffin [J]. CIESC J (化工学报), 2017, 68(6): 2258-

2265.

上,但因含有微量非碱性氮而显色。 [17] Dijkmans T, Pyl S P, Reyniers M F, et al. Production of bio-ethene

(3)加氢脱氮反应中,在反应温度为 310 ℃、 and propene: Alternatives for bulk chemicals and polymers [J]. Green

Chem, 2013, 15(11): 3064-3076.

氢气压力为 2 MPa、氢烃体积比为 2000 和 WHSV

[18] Gosselink R W, Hollak S A W, Chang S W, et al. Reaction pathways

为 0.25 h –1 的工艺条件下,NiMo/Al 2 O 3 能够脱除 for the deoxygenation of vegetable oils and related model compounds

FAMEs 脱氧产品中 90%以上的含氮化合物,获得正 [J]. Chemsuschem, 2013, 6(9): 1576-1594.

[19] Hermida L, Abdullah A Z, Mohamed A R. Deoxygenation of fatty

构烷烃质量分数高于 96%的无色生物烷烃。但产品 acid to produce diesel-like hydrocarbons: a review of process conditions,

的荧光仍无法彻底消除,有待更为高效的吡咯类加 reaction kinetics and mechanism [J]. Renew Sustain Energy Rev, 2015,

氢脱氮催化剂的研发。 42: 1223-1233.

[20] Qian E W, Abe S, Kagawa Y, et al. Hydrodenitrogenation of

porphyrin on Ni-Mo based catalysts [J]. Chi J Catal, 2013, 34(1):

参考文献: 152-158.

[1] Mózes G. Paraffin products [M]. Amsterdam: Elsevier Science Publishers, [21] Wei Q, Wen S, Tao X, et al. Hydrodenitrogenation of basic and

1983:240-329. non-basic nitrogen-containing compounds in coker gas oil [J]. Fuel

[2] Mújika-Garai R, Aguilar-García C, Juárez-Arroyo F, et al. Stabilization of Pro Technol, 2015, 129: 76-84.